F(T)reeform

Year:

Studio:

Site:

Type:

Collaboration:

Tutor:

Studio:

Site:

Type:

Collaboration:

Tutor:

Msc2 / 2019-20

Bucky Lab

Netherland

Ecor product

Akaz, Jasper, Sander

Marcel Bilow

Bucky Lab

Netherland

Ecor product

Akaz, Jasper, Sander

Marcel Bilow

‘ECOR, a composite biomaterial formed from cellulose fibres, pressure, water, heat‘

Teaming up with Ecor’s dutch based development and design center, the project is to create something in their new office space with ECOR material as a building environment showcase with full circular approach.

With current products developed by the company so far, ECOR material has only been produced for planar and single curvature design. To push the boundary of the material, we decided to experiment on the freeform possibility of ECOR. Our goal is to customize a one-off artwork at the centre of their office. The double curvature tree-like structure surrounding the existing column structure showcases the versatility of ECOR material. ‘Art as architecture’, the freeform design will ultimately become the sprout of the office where design and engineering collaborates with each other with one common goal.

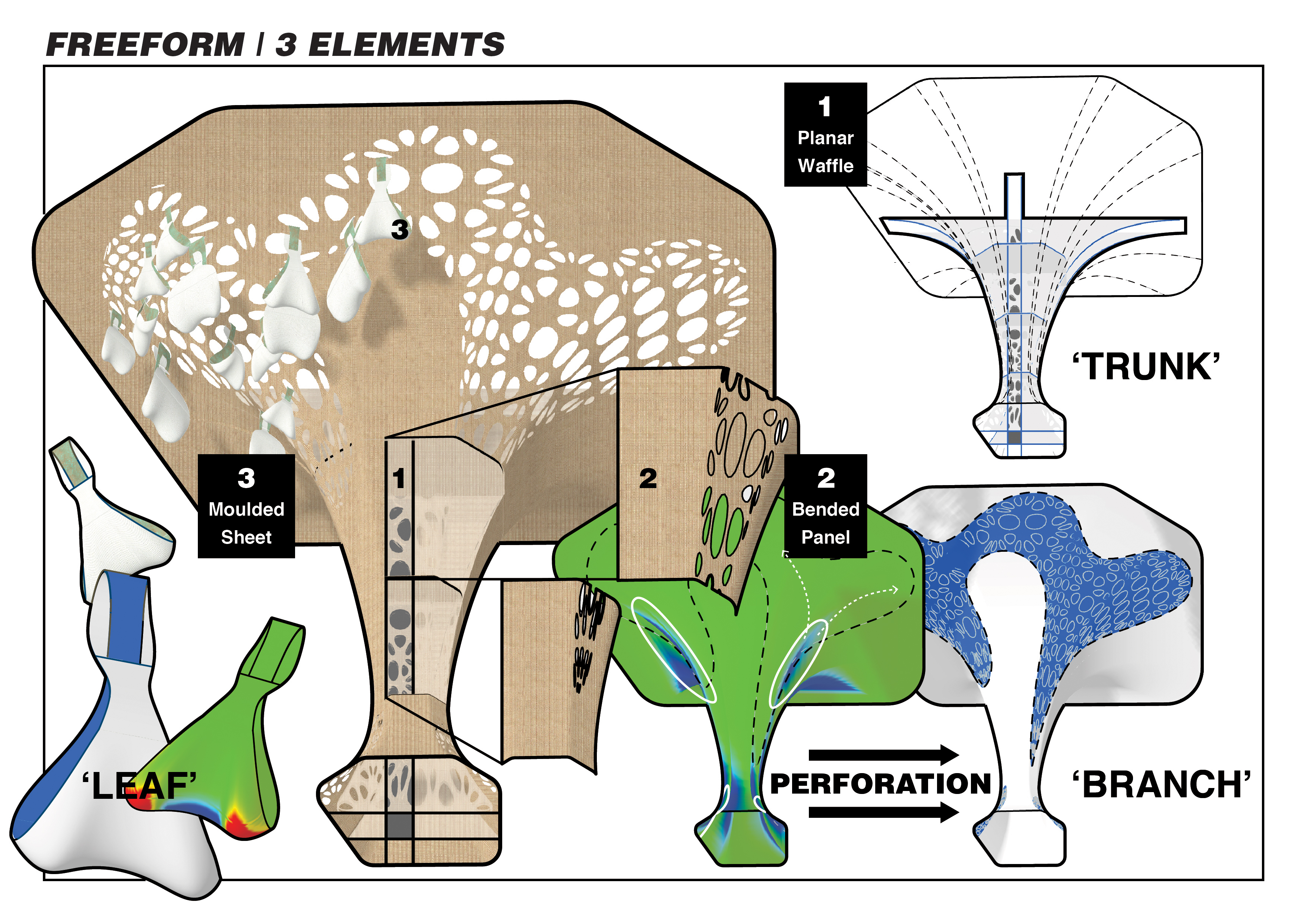

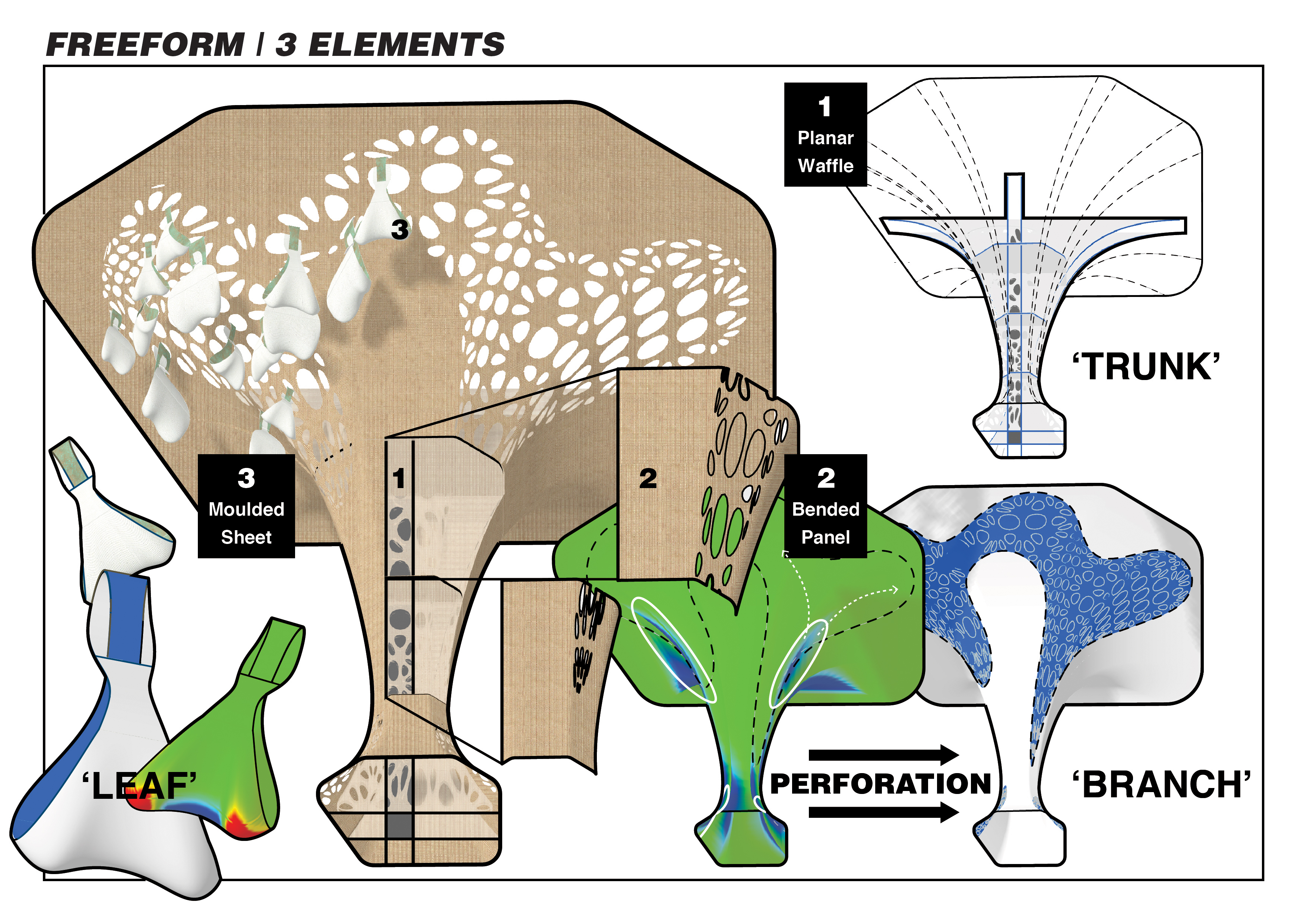

‘Three different techniques for three freeform components’

There are various ways to create a freeform design out of ECOR material. The skeleton of the tree exists out of a planar waffle-structure (1), made with a slit-and-slotting system. Then we will bend ECOR panels (2) against this structure in double curvature. Some of the panels will be perforated to hang the leaves. The leaves will be produced through the technique of moulding (3).

‘Function

follows form’

‘Freeform’ is an aesthetic product putting form as the first priority to create a ‘WOW’ effect. To further present ECOR itself as a bio-based material, ‘freeform’ is a biomimicry design that resonate the form of nature.

From ECOR sheets and raw pulp to double curvature...

For the tree component, we tried to bend the planar ECOR sheets in a double curvature after soaking it into water. Panels were sewed together afterwards. However, extent of curvature is limited. For the leaf elements, we tried paper mache to resemble the properties of the ECOR pulp, of which smooth double curvature was achieved.